The heat press is on the rise. And with it, new trends are developing and new techniques are being offered to further advance how heat presses can be used.

Heat-applied graphics have pushed technological advances on the equipment side to keep pace with the changing landscape of decoration. Heat pressing found it’s niche years ago as the best method for applying names or numbers and turned a menial task into its own profit center. The rise of small-order and print-on-demand business models have made the heat press a cornerstone in any decoration space.

Added Dimensions

Looks inspired by retail, such as molded emblems, embroidered patches and other dimensional products, have spurred a redesign in traditional flat heat presses. Typical heat presses have an upper platen that heats to a temperature and when clamped down applies heat and pressure to bond the chosen decoration and garment.

To achieve better adhesion for these thicker items a press redesigned with bottom platen heating allows for the heat to be in closer proximity to the adhesive allowing for higher accuracy in application. This is especially ideal for molded emblems where improper application can damage the texture or graphic itself.

Time Savers

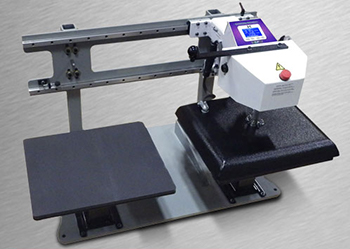

Another innovation is the dual press or shuttle press. These machines offer an additional press platen, allowing a single operator to increase production. They can be configured to increase output but utilizing the operators time that would otherwise be idle during the pressing. This time can now be used to set up and prepare the next garment simultaneously. Additionally, the second station can be set for a completely different process like a back print or sleeve.

Perfect for jobs requiring multiple locations for printing, these type of machines offer a wide array of features and different modes of operation to fit. From manual to automatic operation to multiple platen configurations, these can be tailored to both business and operator needs.

Perfect for jobs requiring multiple locations for printing, these type of machines offer a wide array of features and different modes of operation to fit. From manual to automatic operation to multiple platen configurations, these can be tailored to both business and operator needs.

New Technologies

With the sudden and widely successful introduction of Direct to Film (DTF) Transfers a new type of press has appeared similar in technology to a traditional screen print machine. The heat press carousel offers high output for a single operator and the capability to further increase production — with an additional team member output volume can be greatly increased.

With the sudden and widely successful introduction of Direct to Film (DTF) Transfers a new type of press has appeared similar in technology to a traditional screen print machine. The heat press carousel offers high output for a single operator and the capability to further increase production — with an additional team member output volume can be greatly increased.

Because the operation is like screen printing, the heat press carousel offers quick cross training and is relatively plug-and-play like most heat presses. Carousel machines offer the option of multiple platens as well as additional heating units to further increase production of multiple press applications.

With all the features and options available, now is the perfect time to review your heat press and consider adding some new features that may enhance the profitability of your shop with relatively little of expense.