September 10, 2021

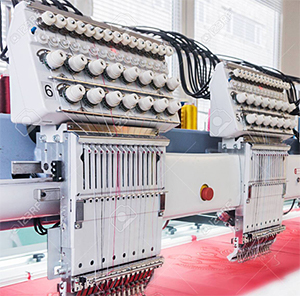

While working on the Decorator and Digital Solutions Team, I have seen my share of broken needles on embroidery machines. It could be while embroidering on structured caps, heavy duck cloth material, bags or any number of items. But this doesn’t have to be the case!

There are some simple steps to stop the break before it happens. Here are some of our best practices — hope they help you (and your needles):

- Embroidery needle size

The most typical needle size used in machine embroidery for mid-weight fabrics is 75/11. If you are embroidering something heavier, like leather or denim, you should move up to a heavier needle, like 90/14s. - Embroidery needle type

Make sure you are using needles specifically for machine embroidery. It makes a difference. - Embroidery needle brand

Embroidery machines are finicky, so be sure to experiment by using different needles. See which one your machine likes better. While it’s hard to see the disparities between needles, subtle differences can have a big impact. Some needles have a small eye and so the thread can’t move around as much, which can be beneficial when you are stitching with slippery polyester thread. - Embroidery needle material

Most needles are made of chrome-plated steel. However, there are titanium needles available which are stronger. They cost a bit more than standard needles but they typically last longer. - Embroidery needle installation

Is your needle installed correctly? The flat part of the needle should always face toward the back of the machine. Also, the screw that holds the needle in place can be loose, which can cause the needle to wobble around. Make sure it’s tight. And finally, it could be that the needle isn’t installed as far in as it needs to be. - Embroidery needle condition

Check to see if your needle is warped. If your needle does not appear perfectly straight, it’s time to replace it. A warped needle can hit the presser foot, which will cause the needle to break. - Threading the embroidery machine

Check that your thread isn’t getting caught up or snagging on anything as if flows through your machine. The tiny slot on the thread spool can catch your thread and prevent it from flowing properly. It must be turned away from the line of thread feeding. Even if you don’t see an immediate problem with the threading, turn machine off and unthread it. Also, be sure to thread the machine with the presser foot up. The added tension can cause issues.

Check that your thread isn’t getting caught up or snagging on anything as if flows through your machine. The tiny slot on the thread spool can catch your thread and prevent it from flowing properly. It must be turned away from the line of thread feeding. Even if you don’t see an immediate problem with the threading, turn machine off and unthread it. Also, be sure to thread the machine with the presser foot up. The added tension can cause issues. - The DST file

If your needles are breaking repeatedly on the same design, it may be a design flaw. The digitizer might have left too many layers of stitching in one spot, making it very dense, and causing the needles to break. If you suspect this is the problem, contact the digitizer. - Embroidery machine speed

Needles can bend on heavier fabric and structured caps when working at fast speeds. And once they are bent, they break quickly. - Embroidery machine tension setting

If your tension is too tight, it can cause the needles to break. - Embroidery machine bobbin

Make sure the bobbin is in the right way and that it is threaded properly. Until I knew better, I was putting my bobbin in the bobbin cage backward and I would frequently break needles because the bobbin thread was not feeding properly.

If you have any questions, contact us at the Decorator and Digital Solutions team at decoratorrelations@sanmar.com.