I remember when growing up, I was on a competitive swim club and we’d travel many weekends to different cities in the Midwest for two-day meets. There they would be selling patches to put on your warmups to show you participated at that meet. My mom would put it on manually with a needle and thread.

Patches have been around in some capacity for centuries, but it was machinery developed during the Industrial Revolution that changed the game for garment production. Sewing machines, particularly those produced by the Merrow Sewing Machine Company, paved the way for the cap patches we know and love today. The government saw how useful patches were to identify divisions and rank members in the military. Today you’ll see embroidered patches all over the place, from uniformed personnel to high school letterman jackets.

Patches have been around in some capacity for centuries, but it was machinery developed during the Industrial Revolution that changed the game for garment production. Sewing machines, particularly those produced by the Merrow Sewing Machine Company, paved the way for the cap patches we know and love today. The government saw how useful patches were to identify divisions and rank members in the military. Today you’ll see embroidered patches all over the place, from uniformed personnel to high school letterman jackets.

Patches began their journey in the 1960s when people put them on jeans and denim jackets, used to repair damaged clothing. That was the worst when I wore out the knee area on my pants and a patch applied in that area then had to wear to school.

There are several distinct types of custom patches out there, and it can be overwhelming for people who are not already familiar with the use of each type. When it comes to choosing the perfect type of custom patch for you, there are several distinct aspects that must be considered, such as price, material, turnaround time, durability, texture, and so much more. Some of the options are:

There are several distinct types of custom patches out there, and it can be overwhelming for people who are not already familiar with the use of each type. When it comes to choosing the perfect type of custom patch for you, there are several distinct aspects that must be considered, such as price, material, turnaround time, durability, texture, and so much more. Some of the options are:

- Embroidered patches

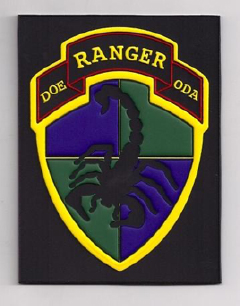

- PVC patches

- Silicone Patches

- Chenille patches

- Woven Patches

- Leather Patches

- Name Patche

- Velcro patches

After speaking with decorators, they have suggested the best ways to apply patches:

After speaking with decorators, they have suggested the best ways to apply patches:

- Patches that have an adhesive on the back to Heat press the patch on

- Stitching the patch down with a post bed industrial sewing machine

Some decorators have success on their embroidery machine, but point out that you must watch the shape and the physical dimensions of the patch. Patches over two inches in height and width could cause the registration to be off. Patches that are circular, squared, and rectangular have the best success.

In the industry, we have companies that will make and ship patches to you:

- Penn Emblem

- Stahl’s

- Flex Systems

- The Studio

- And many more

Cap patches are the most coveted style for because they give caps the look and feel of a retail product. Caps are not the only product; decorators can apply patches to:

Cap patches are the most coveted style for because they give caps the look and feel of a retail product. Caps are not the only product; decorators can apply patches to:

- Bags

- Warmups

- Work Wear

- Polos

- Towels, blankets, and aprons

- Outerwear

With so many options, there are pretty much endless variations on how and when you can use patches in your decoration. I hope this has helped inspire a few ideas for you!