Polyester fabrics have become ubiquitous in our modern world, adorning everything from clothing to upholstery. This popularity stems from its durability, affordability, and versatility. However, not all polyester fabrics are created equal, especially when it comes to compatibility with dye sublimation printing.

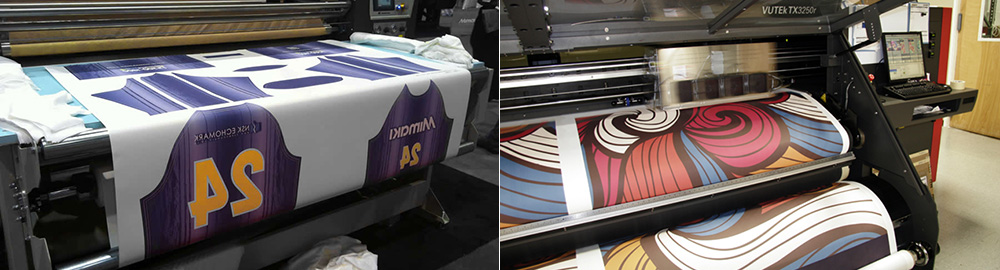

Dye sub is a popular decoration method that molecularly bonds a design’s ink to the fabric materials, using a highly elevated heating process. It offers vibrant, long-lasting colors and is most commonly used for creating custom apparel, signage, and promotional items. Unlike other decoration methods, designs added through dye sublimation become part of the material itself and feel the same as the rest of the fabric.

Types of Polyester Fabrics

- 100% Polyester: This is the most common type of polyester fabric used in dye sublimation printing. It is made entirely of polyester fibers, which makes it ideal for retaining vibrant colors and sharp images for a long time.

- Polyester Blends: Some polyester is blended with other materials such as cotton or spandex to enhance properties like stretch, drape, and breathability. While these blends can still be compatible with dye sublimation printing, the presence of other fibers will affect the final result. For example, cotton blends may result in a more muted color palette, and spandex blends may cause distortion in the printed image due to the fabrics elasticity.

- Coated Polyester: Certain polyester fabrics are coated with substances like polyurethane or PVC to add water resistance or other properties. While these coatings can provide additional functionality to the fabric, they may interfere with the sublimation process by preventing the dye from properly penetrating the fibers.

- Recycled Polyester: While the growing trend of recycled polyester represents an excellent choice for environmentally-conscious customers, you should be aware of its limitations when it comes to decoration. Recycled poly is more prone to dye migration and color sheen change, and has a lower tolerance for heat. If you’re planning to explore dye sublimation on recycled polyester, proceed with caution and plenty of testing.

Factors Affecting Dye Sublimation Compatibility

- Garment Design: Clothing you see in retail is often dye sublimated prior to cutting and sewing to avoid imperfections that can arise at the seams or folds. When you’re doing all-over sublimation on an existing garment, look for one with extremely flat seams and straight, flat arms. However, the vast majority of dye sub decorations are spot sublimations on the left chest or another common localized area.

- Fiber Content: The higher the polyester content, the better the fabric will typically respond to dye sublimation. In a poly/cotton blend or tri-blend with less than 65% polyester, the dye will not bond to the cotton and will eventually wash out, resulting in dull colors and blurry images compared to the same decoration on a 100% polyester fabric.

- Fabric Weave: The weave structure of the fabric can impact how well it absorbs and retains dye. Tighter weaves tend to yield sharper prints, while looser weaves may result in more diffuse colors.

- Surface Finish: Fabrics with smooth, flat surfaces are generally more compatible with dye sublimation compared to those with textured or coated finishes. For example, the Sublimation Rally Towel and Beach Towel feature a 100% poly velour facing for sublimation, with a cotton backing. Textured surfaces can disrupt the transfer process and lead to inconsistencies in the printed image.

- Color: Light-colored fabrics are preferable for dye sublimation printing because they allow the dye to fully saturate the fibers and produce vibrant colors. Whatever the color of the shirt, make sure that the ink colors are darker than the fabric color to get the desired look of the final sublimated decoration.

In conclusion, while polyester fabrics are widely used in dye sublimation printing, not all polyester fabrics are created the same in terms of compatibility. It’s essential to consider factors such as fiber content, fabric weave, surface finish, and color when selecting polyester for dye sub projects. By choosing the right fabric for the job, you can ensure optimal print quality and durability.